ACCURACY IN FORM

Flow forming achieves precise dimensions and uniform wall thickness, ensuring consistency across every part.

STRENGTH IN DESIGN

The process enhances mechanical properties, creating components that are both lighter and stronger than those made by conventional methods.

VERSATILITY IN APPLICATION

From aerospace structures to defense systems and industrial uses, flow forming supports a wide range of critical industries.

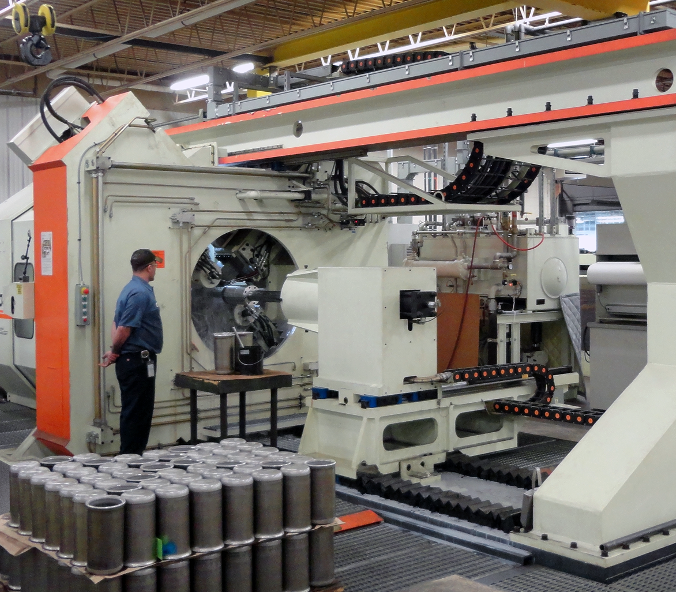

Flow forming is a highly precise metalworking process that enables the production of lightweight, high-strength cylindrical parts built for demanding applications in aerospace, defense, energy, and beyond. By gradually shaping metal over a mandrel with exceptional accuracy, the process produces components with superior mechanical properties and reduced material waste compared to traditional methods. ViDARR delivers flow formed parts ranging from ½” to 48” in diameter and up to 90” in length, ensuring flexibility across a wide range of mission requirements. Working alongside a trusted partner, we combine advanced engineering expertise with proven manufacturing techniques to deliver reliable, high-performance results that meet strict industry standards.

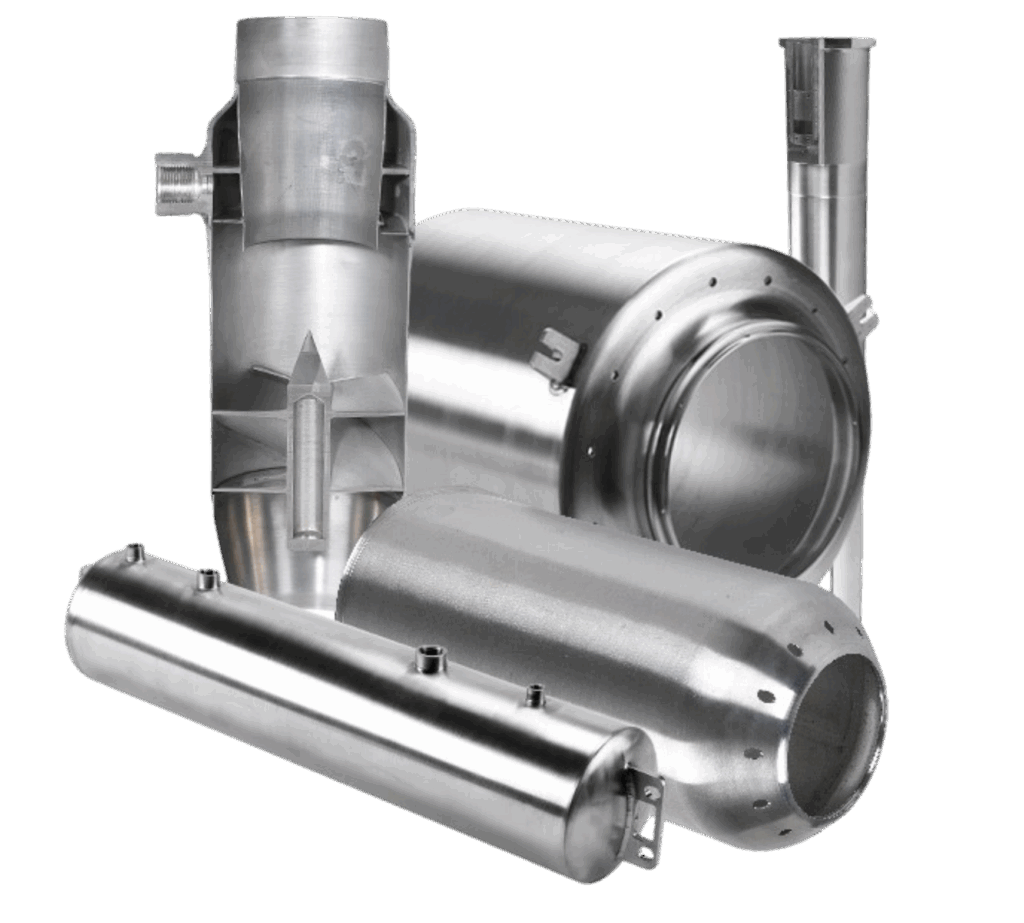

Cylinders

Achieve lightweight yet incredibly strong housings with PMF Industries’ custom flowformed solutions. Our partner's expertise in metal forming delivers intricate shapes and seamless construction for demanding applications like aerospace gear housings, medical device enclosures, and industrial pump housings.

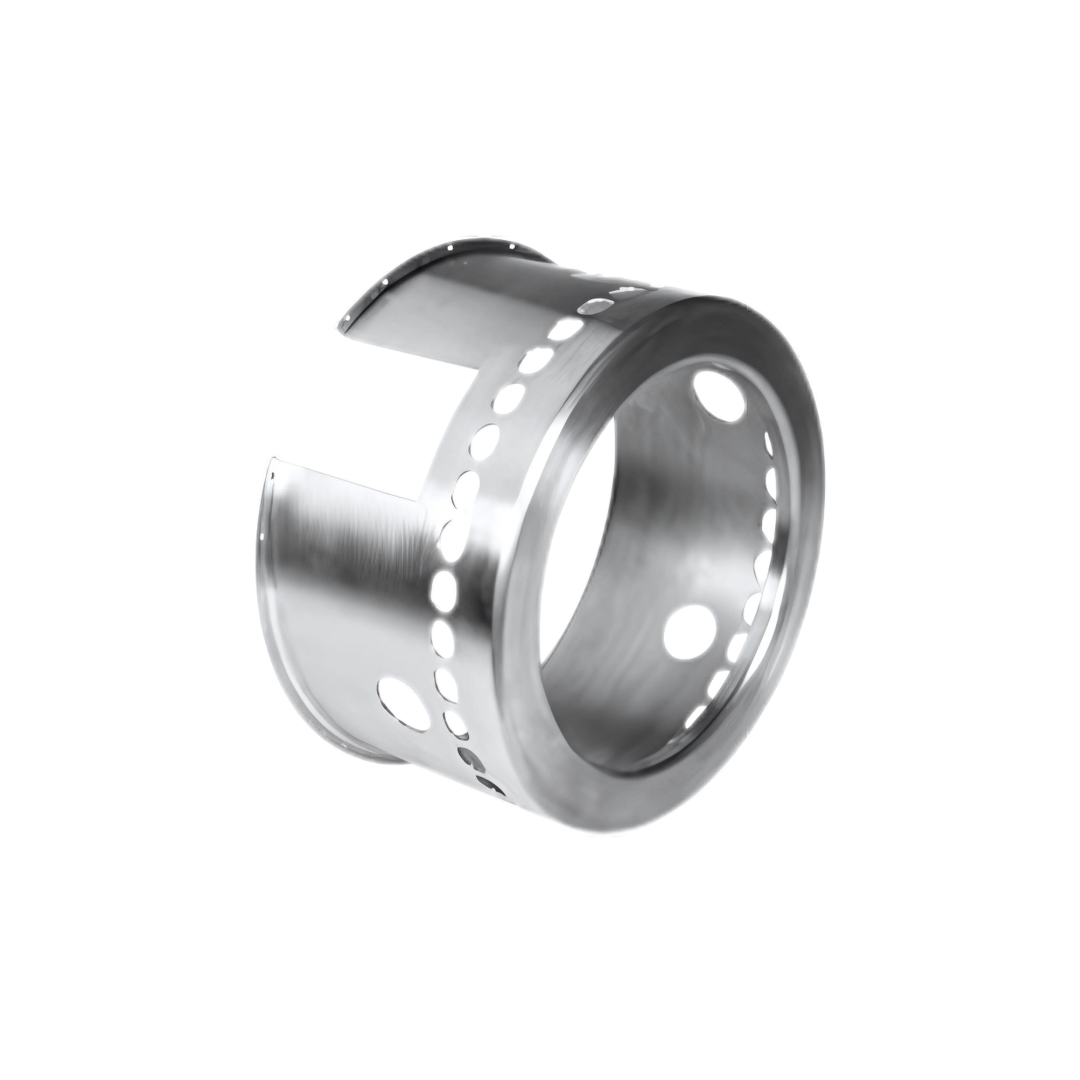

HOUSINGS

Need custom cylinders with exceptional dimensional accuracy and tight tolerances? By leveraging precision metal flowforming, our partner can create cylinders with superior surface finishes and complex geometries, ideal for aerospace drive shafts, hydraulic cylinders, and industrial rollers.

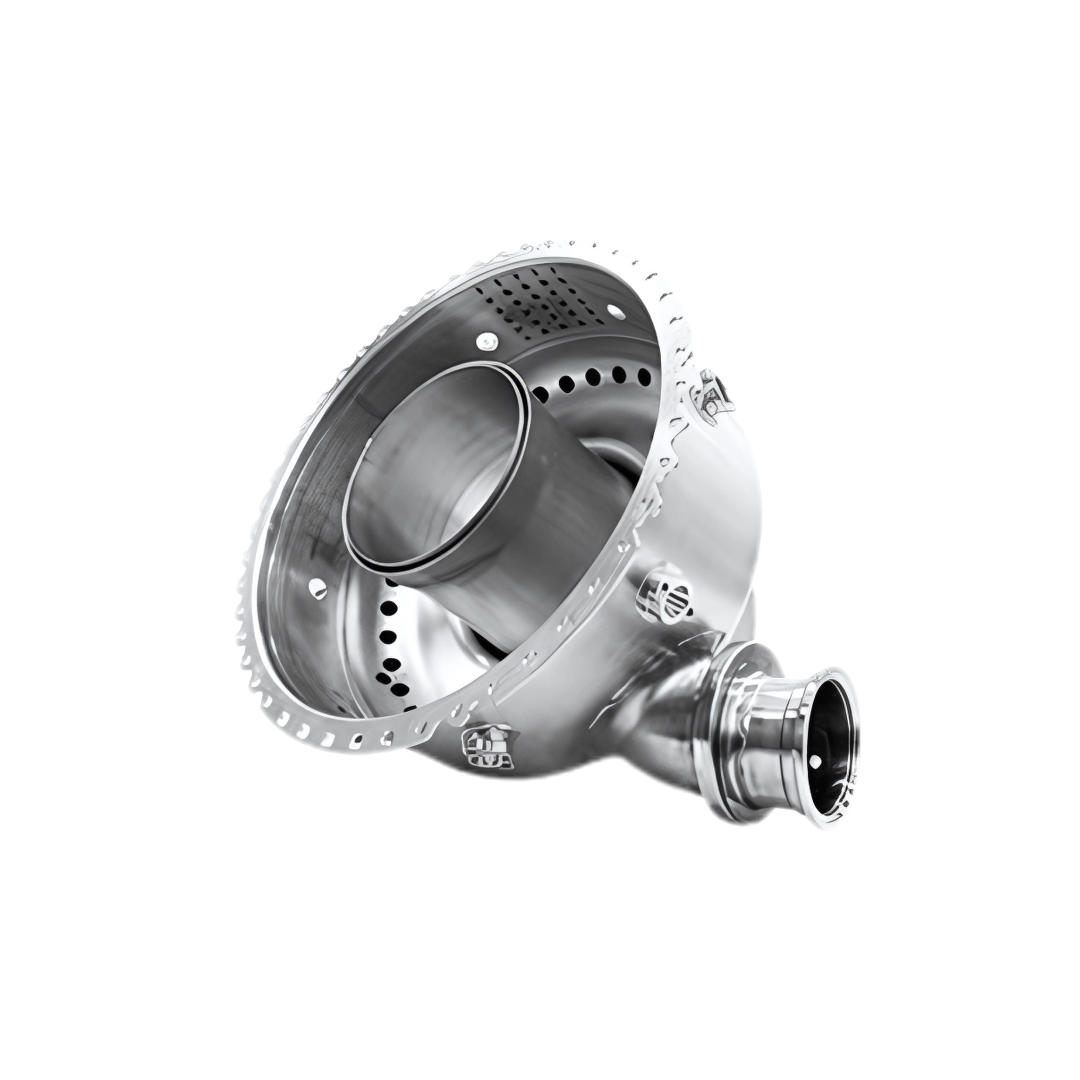

CONES & FUNNELS

Optimize flow and performance with custom flowformed cones and funnels. These custom components achieve precise geometries and smooth transitions, essential for aerospace nozzles, filtration systems, and chemical processing equipment.

VESSELS

When your application demands high strength, durability, and corrosion resistance, choose our custom flow-formed vessels. These custom metal components are seamlessly constructed with uniform wall thicknesses, ideal for aerospace fuel tanks, energy storage tanks, and chemical processing vessels.

COMPLEX ASSEMBLIES

Streamline your production with our partner's complex flowformed assemblies. We serve the aerospace, defense, and industrial sectors, combining “flowforming” with machining, welding, and heat treating to deliver complete solutions for landing gear, weapon systems, and specialized machinery.

MILITARY FLOW FORMING OFFERINGS

- 332710: Machine Shops

- 332721: Precision Turned Product Manufacturing

- 332811: Metal Heat Treating

- 332993: Ammunition (Except Small Arms) Manufacturing

- 332995: Other Ordinance and Accessories Manufacturing

- 332999: All Other Miscellaneous Fabricated Metal Product Manufacturing

- 333242: Semiconductor Machinery Manufacturing

- 333291: Paper Industry Machinery Manufacturing

- 333294: Food Product Machinery Manufacturing

- 336412: Aircraft Engine and Engine Parts Manufacturing

- 336414: Guided Missile and Space Vehicle Manufacturing

- 336415: Guided Missile and Space Vehicle Propulsion Unit and Propulsion Unit Parts Manufacturing

- 336419: Other Guided Missile and Space Vehicle Parts and Auxiliary Equipment Manufacturing